Press Tooling

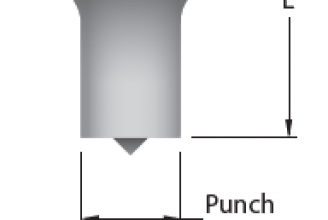

Punches

Tipco manufactures standard and special tooling used in stamping dies, die cast dies, and plastic injection molds. We provide machining services, call us today!

Learn More

Die Buttons

Counterbore relief die buttons are catalog items at Tipco and taper relief die buttons are available upon request. Contact us today for more information!

Learn More

Ironworker Tooling

Tipco manufactures and stocks a wide variety of ironworker punches and die buttons. Tipco stocks a wide range of standard ironworker punches and dies.

Learn More

Retainers

Retainers hold a headed or ball lock punch into position within the stamping die. We offer ball lock punch retainers, end and square type retainers in both heavy and light duty from stock.

Learn More

Die Springs

Mechanical die springs are used in both stamping dies and plastic injection molds. We offer a full line of die springs in ISO and US standards. Call us today!

Learn More

Nitrogen Gas Springs

Nitrogen gas springs are another method of returning stripper plates to their original position, to create a positive return for a cam, punch or to actuate a die component into position within the stamping die.

Learn More

In Die Tapping Units

In-die tapping is an alternative to secondary tapping or using a weld nut, yielding a better fastener at a lower total cost. Contact us today for more!

Learn More

Hydroform Tooling

The development of hydroforming technology began in the late 1940’s and early 1950’s and continues to evolve to this day.

Learn More

Precision Components

This mix of equipment positions Tipco to fulfill a wide range of customer applications in small, medium, to large production runs.

Learn More